What is BRCGS and why does traceability sit at its core?

The British Retail Consortium Global Standard (BRCGS) sets the rulebook for food safety, quality, and operational criteria. BRCGS traceability section 3.9.3 of the standard demands that you can trace every raw material “one step back and one step forward” within 4 hours-often faster.

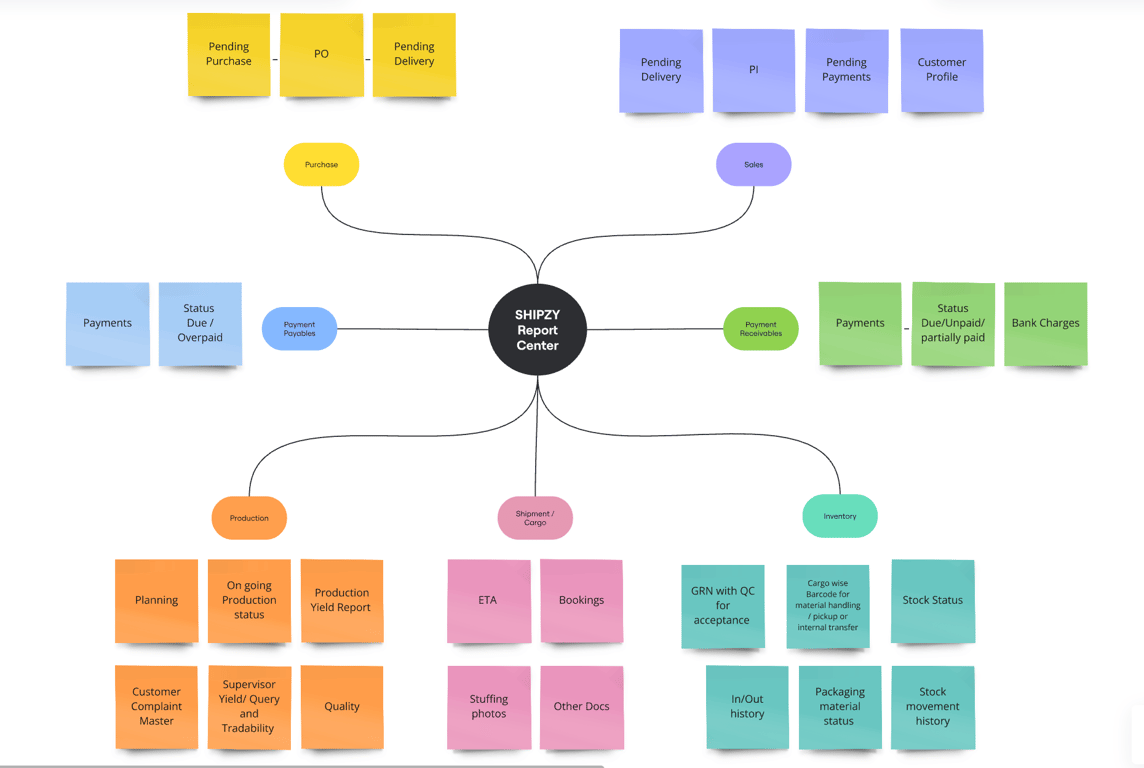

Key modules in a BRCGS-ready traceability platform Shipzy

| Module | How it meets BRCGS clauses | Everyday pay-off |

|---|---|---|

| Raw-Material Intake - GRN | Captures supplier approval status, COAs, and identity checks (Clause 3.5) | No more hunting for missing vendor documents during audits |

| Batch Production & Formulation | Auto-generates lot codes that preserve provenance (Clauses 4.9 & 4.10) | Pinpoint a suspect spice lot in seconds |

| Quality & Hazard Control | Links CCP/PRP checks, lab results, and NCR workflows (Clause 2) | Flags deviations before they snowball |

| Inventory & Warehousing | Enforces FIFO/FEFO, temp/humidity logs (Clause 4.8) | Less wastage, longer shelf life |

| Goods Movement & Dispatch | Creates tamper-proof records of every transfer (Clause 4.11) | Provides instant proof of chain-of-custody |

| Recall & Incident Manager | Runs mock recalls and auto-generates trace reports (Clause 3.11) | Drill → print → done-auditor smiles |

| Compliance Dashboard | Live KPI tiles for audit status, overdue actions, supplier scores | Pull a full compliance pack in one click |

How the workflow plays out - Example

-

GRN – Raw cumin seeds arrive; GRN ties them to supplier, farm, pesticide test.

-

QC Gate – Lab results pass; software releases lot to Batch Production.

-

Blending & ETO– Each stage logs operator, machine, parameters.

-

Packaging – Finished batch inherits the full ingredient track automatically.

-

Dispatch – System prints BRCGS-compliant labels and shipping docs.

-

Audit Day – Auditor requests a mock recall; you search Lot CUM-123-B, hit submit, and hand them a PDF showing input-to-customer chain within 30 seconds.

-

Digital SOP library with version control for every BRCGS clause.

-

Supplier Scorecards that auto-downgrade vendors if they fail a test.

-

API hooks to e-Way Bill, e-Invoice, and customs portals so documents stay synced.

ROI snapshot

| Pain Point | Old Way | With BRCGS Traceability Software |

|---|---|---|

| Audit prep | 2-3 weeks of manual file chasing | < 1 day auto-generated packs |

| Mock recall drill | 4-6 hours, high stress | < 5 minutes, zero issues |

| Product holds due to data gaps | Frequent | Rare to none |

| Team busy in paperwork | High | 40-60 % reduction |

Getting started-best-practice rollout

-

Map current lot-coding rules-standardise them before software import.

-

Pilot one product line to fine-tune CCP logging and recall reports.

-

Train QA first; once quality is on board, Ops and Sales will follow.

-

Schedule an annual mock recall-treat it like a fire drill.

Ready to turn audit day into just another productive Tuesday? Book a demo and see how Shipzy traceability keeps you compliant, confident, and ahead of the curve.

Trademark notice

“BRCGS” and the associated logos and certification marks are registered trademarks owned by BRCGS and used under licence. All references to BRCGS in this material are purely for descriptive or comparative purposes; no affiliation with, endorsement by, or sponsorship from BRCGS is implied. All other product names, brands, and logos remain the property of their respective owners.